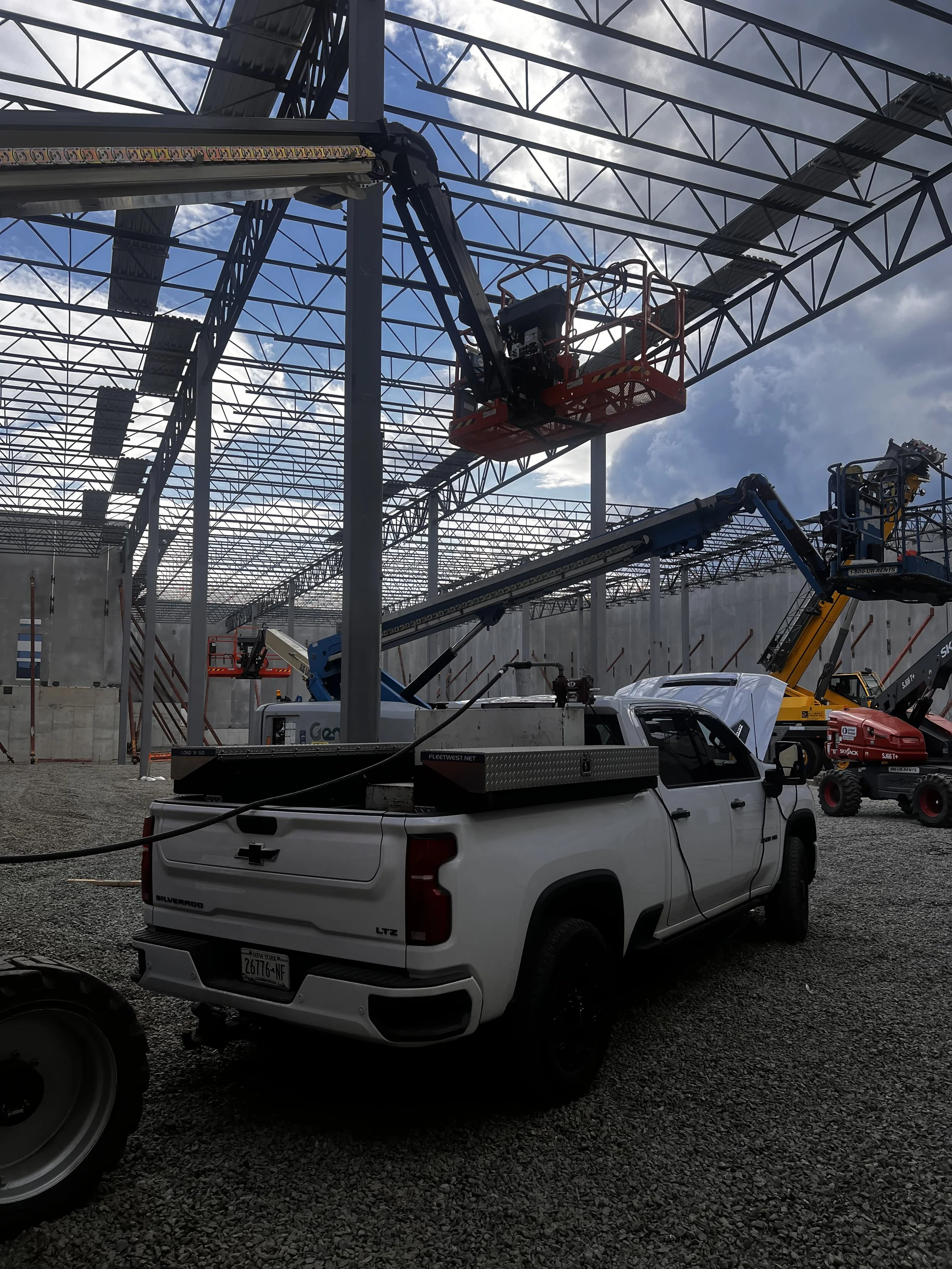

Structural Steel.

What is

Structural Steel?

Structural steel is essential for building institutions, commercial spaces, and industrial facilities, requiring accuracy

and skill.

Our team fabricates and assembles beams, columns,

and structural frameworks to meet specific project requirements and engineering standards. Each piece is carefully cut, welded, and finished to ensure strength, safety, and long-term performance on-site.

-

Structural steel cutting is the first step in the fabrication process. Using tools like saws, torches, or CNC plasma cutters, we shape raw steel into precise dimensions per project specs.

-

We drill clean, accurate holes for bolts and anchors using high-performance equipment. Proper alignment here ensures strong and safe structural connections.

-

Welding is where strength comes together. Our certified welders use proven methods to ensure lasting durability. Each weld is inspected for quality and safety.

-

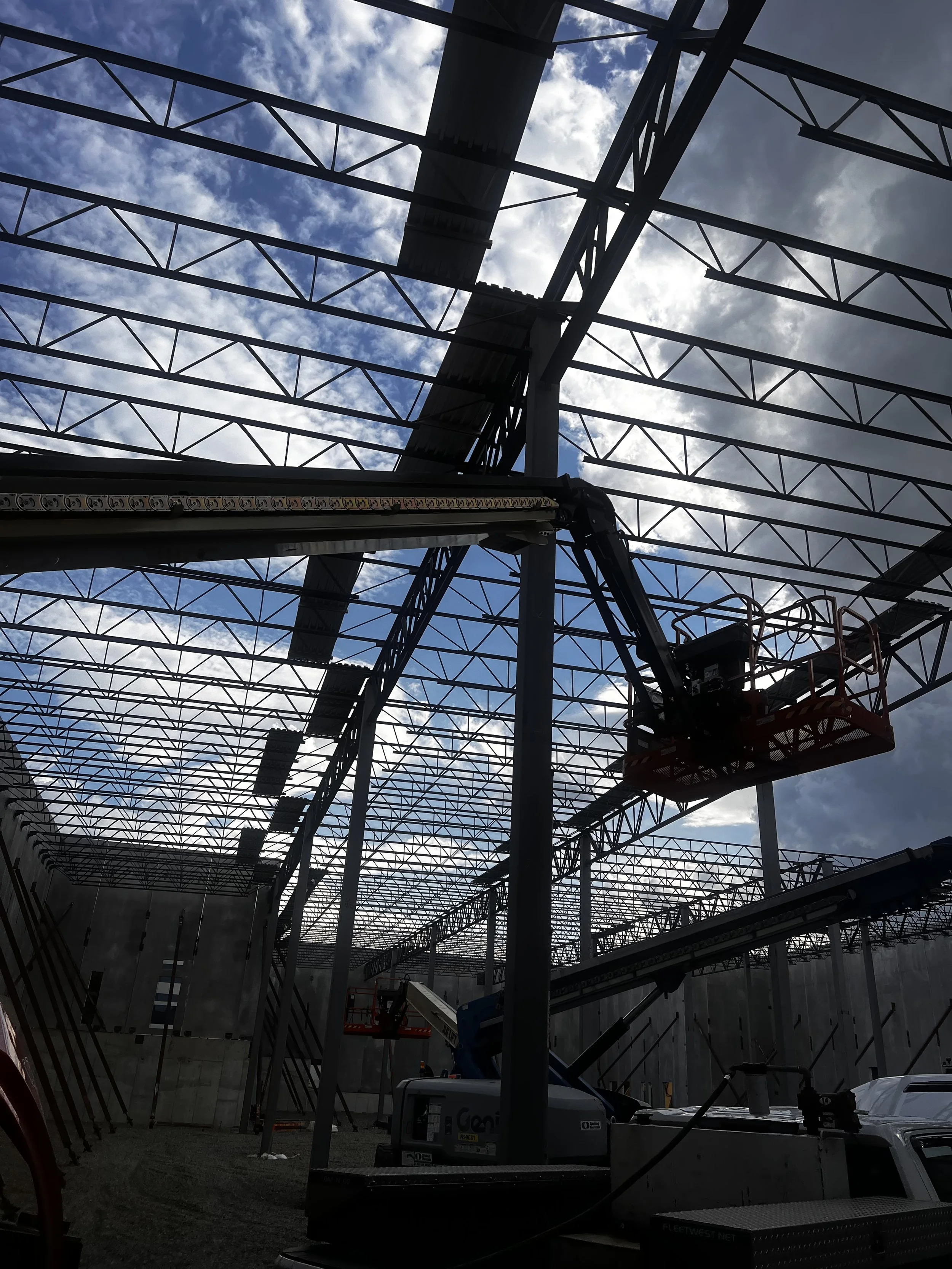

This is the stage where all parts come together. Our team carefully aligns and assembles cut, drilled, and welded components into full structural systems, ready for efficient installation.

Structural Steel Process.

Metal fabrication involves the hands of many skillful professionals over different processes.

Structural Steel Elements.

Beams and columns

Structural frames and supports

Bracing systems

Mezzanines and platforms

Equipment skids

Moment connections

Base plates and embed plates